Reducing "Waste" in Repair Costs with AI | How to Create Equipment Management Guidelines from Past Data

Use AI to analyze past repair costs and pinpoint wasteful spending patterns like employee negligence or poor purchasing choices. Learn how to extract these insights and build an effective guideline outline to prevent recurring expenses and optimize your budget.

Why "Waste" in Repair Costs Can't Be Prevented

When repair costs that should have been preventable keep recurring, there are usually three main reasons:

- The root cause isn't recorded

Repair reports often only say "replaced due to damage," but the fundamental reason—"why did it break?"—is never tracked. - Equipment selection relies on "experience and intuition"

Are you choosing supplies just because "we’ve always used this" or "it’s cheap"? This often leads to a "penny wise, pound foolish" situation where long-term costs actually end up higher. - Information isn't accumulated within the organization

Because repair and purchase histories are managed separately, information on "which items break most often" isn't shared across the team. When a manager moves on, the same mistakes are repeated.

With AI, You Can See "True Causes" and "Cost-Cutting Measures"

mitsumonoAI’s "File Analysis Assistant" derives specific cost-reduction measures from repair data that was previously overlooked. For the hospitality industry, for example, the following types of analysis are possible:

- Categorizing causes from free-text descriptions

AI automatically classifies various reasons like "dropped during cleaning" or "spilled by a guest" into categories such as "Employee Negligence," "Equipment Quality Issues," or "Damage by Guest." This makes the primary cost drivers clear at a glance. - Discovering data correlations

AI detects patterns that are hard for humans to notice, such as "this cheap hair dryer consistently fails within 3 months" or "the shoji screens in this specific guest room are damaged once a month." - Creating specific, actionable guidelines

Rules you can implement starting tomorrow—like "Switch from Hair Dryer A to a different model" or "Standardize cleaning procedures in guest rooms to prevent damage"—are automatically generated.

In Practice | 3 Steps to Identify Waste in Repair Costs (Example: Hospitality)

Step 1: Summarize Your Repair History Data (Excel or CSV)

Organize your past repair records into an Excel or CSV file. Please use the following categories:

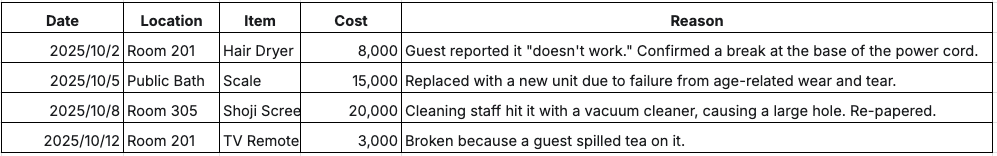

Example Repair History Data

Upload this file to the "File Analysis Assistant" in mitsumonoAI.

Step 2: Instruct the AI to Analyze

Give the AI instructions like the following:

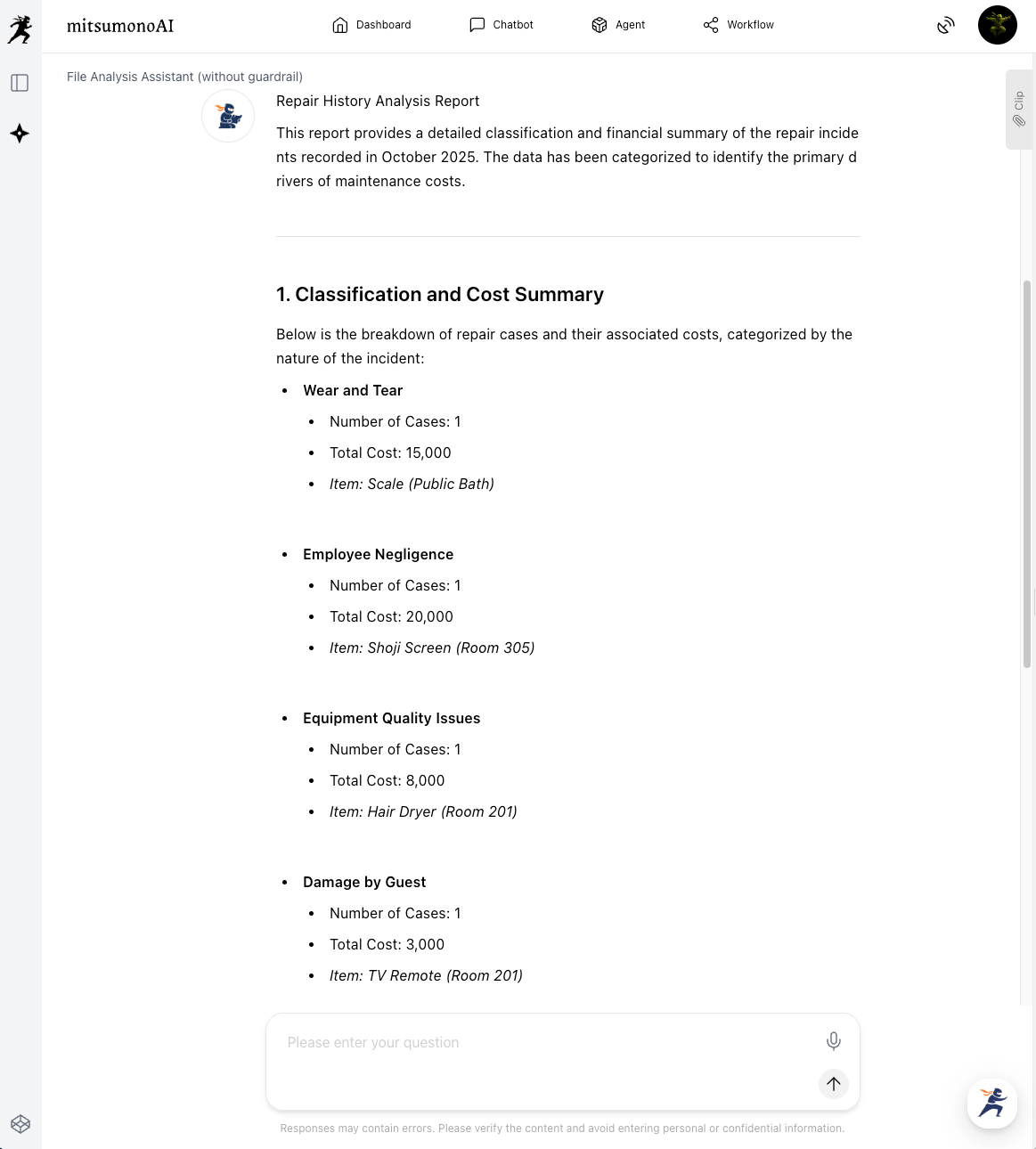

"Analyze this repair history and create a report that:

1.Classifies repair reasons into 'Wear and Tear,' 'Employee Negligence,' 'Equipment Quality Issues,' and 'Damage by Guest.'

2.Totals the number of cases and costs for each category.

3.Points out patterns with particularly high costs or frequencies, excluding standard wear and tear."

This completes the classification and tallying of the causes.

Step 3: Create "Equipment Management Guidelines" through AI Dialogue

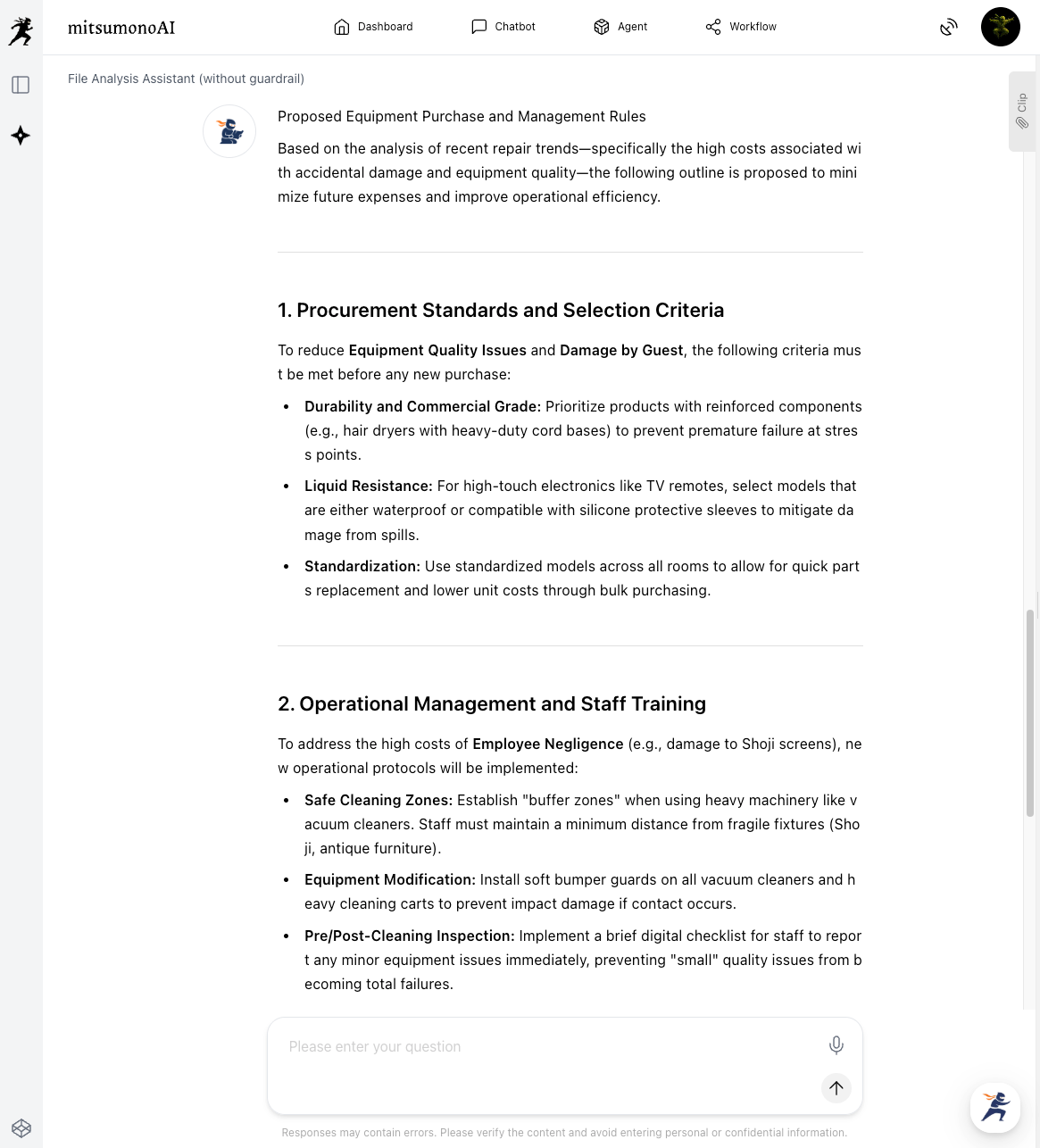

Based on the report the AI generated, have it create even more specific guidelines.

"Based on these analysis results, please propose an outline for future equipment purchase and management rules."

Review the generated guidelines internally and establish them as operational rules.

✅ Does Your Guideline Meet These 5 Criteria?

Check if the AI-generated guidelines are truly practical:

- Is it shown in numbers?

Does it include specific figures, like "Estimated cost reduction rate of X%"? - Are there measures for specific items?

Is it clear what to change and how, such as "Switch this item to Company Y's product"? - Are there location-specific measures?

Are there rules for specific areas, such as "Standardize cleaning procedures to [Method Z] for Room XX due to high damage frequency"? - Is it clear who does what?

Is the division of roles clear, like "Purchasing manager will do..." or "Cleaning staff will do..."? - Can it be implemented immediately?

Are the rules realistic enough to start using tomorrow?

Summary: Repair History is a Business Textbook

The repair records you keep every day are more than just a list of costs. If analyzed correctly, they become the best source of information for preventing waste. AI finds correlations in this data that humans might miss and turns them into concrete cost-reduction strategies.

For ryokan and hotel owners looking to reduce repair costs, I highly recommend trying this analysis.

mitsumonoAI can be used not only for facility management data analysis but also for solving various business challenges, improving operational efficiency, and creating new value.

For more use cases and the latest information, visit the mitsumonoAI blog site.

![[Tourism DX & Regional Revitalization] A Guide to Materializing Ideas with AI Experts | Realizing Projects Through "AI Sparring"](/content/images/size/w600/2026/01/tourism-dx-senseiai-1.png)